Project Status

Home > News > Project StatusWOM Banji Project Company completes the cleaning of the main transformer cooler

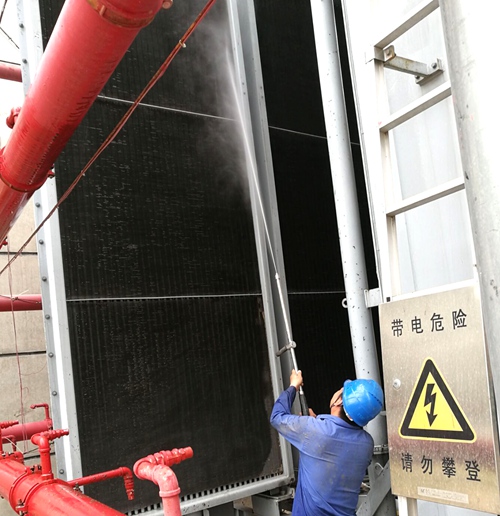

With the coming of summer, the temperature gradually rises. The main transformer cooler of unit #2 in Banji Power Plant runs for a long time. The heat exchanger fins of the main transformer cooler accumulate more ash, and the poor heat dissipation ability affects the safe and stable operation of the unit. On July 5th, Electrical instrument professionals use the mediation opportunity of Unit #2 in Banji Power Plant to flush the heat exchanger fins of the transformer cooler of Unit #2.

The high-pressure water gun is used to flush the heat exchanger fins of the cooler. Before the work, the members of the working class wrapped the cooler tapping power control box, the power control box, secondary terminal box and oil pump junction box in plastic rain-proof cloth, so as to prevent damage to the equipment caused by water inflow into the electrical junction box. After the work permit, the person in charge of the work shall make a safe confession to the members of the work class, and the deputy manager of the project company shall supervise the work on the spot so as to eliminate the phenomenon of irregularities. After one day's efforts, the dust on the hot fins of No. 2 main transformer in Banji Power Plant has been cleaned up, and the efficiency of No. 2 main transformer cooler has been improved significantly, which provides a safety guarantee for peak summer.